In any electrical installation project, choosing the right components and equipment is crucial to ensure optimum functioning and safety. Two common options for managing and protecting electrical cables are conduit fittings and cable trays. Understanding the differences between these two options and their advantages and disadvantages can help you make an informed decision for your project. Let’s explore both conduit fittings and cable trays in detail to help you make the right choice.

Understanding Conduit Fittings

Conduit fittings are essential components used to connect and protect electrical cables in various applications. These fittings act as enclosures for the cables and provide a secure pathway while preventing any damage or interference. Understanding their definition, function, types, and pros and cons can help you evaluate whether conduit box fittings are the right choice for your project.

Definition and Function of Conduit Fittings

Conduit fittings refer to the various components and accessories that connect and secure electrical conduits in place. They are designed to protect the cables from external elements such as moisture, dust, and physical damage. Moreover, conduit fittings provide ease of installation and maintenance, ensuring the longevity and reliability of the electrical system.

When it comes to the function of conduit fittings, they play a crucial role in maintaining the safety and efficiency of electrical installations. By enclosing the cables, these fittings prevent accidental contact with live wires, reducing the risk of electrical shocks and fires. Additionally, conduit fittings offer mechanical protection, shielding the cables from potential damage caused by impact, vibration, or environmental factors. Click here to also understand the basics of smart light switches.

Furthermore, conduit fittings provide a secure pathway for the cables, ensuring that they are properly routed and organized. This organized arrangement not only facilitates easy identification and troubleshooting but also allows for future expansion or modification of the electrical system without major disruptions.

Types of Conduit Fittings

There are several types of conduit fittings available, each catering to specific installation requirements. Common types include elbows, couplings, connectors, bushings, and junction boxes. These fittings are made from materials such as steel, aluminum, PVC, and fiberglass, offering different levels of durability, flexibility, and resistance to corrosion.

Elbows are used to change the direction of the conduit, allowing for smooth routing around corners or obstacles. Couplings, on the other hand, are used to join two sections of conduit together, ensuring a secure and continuous pathway for the cables. Connectors serve as a means of attaching conduit to electrical boxes or other equipment, providing a reliable connection point.

Bushings are used to protect the cables from sharp edges or rough surfaces within the conduit, reducing the risk of insulation damage. Junction boxes, also known as pull boxes, are used to house connections or splices, providing a convenient access point for maintenance or troubleshooting.

Pros and Cons of Using Conduit Fittings

Like any electrical solution, conduit fittings come with their own set of advantages and disadvantages. One of the main advantages is their ability to provide excellent cable protection, ensuring the safety of both the cables and the individuals working around them. Additionally, conduit fittings offer a clean and organized appearance, which is beneficial for projects that require aesthetic appeal.

Another advantage of using conduit fittings is the flexibility they offer in terms of installation. With various types and sizes available, it is possible to customize the conduit system to meet specific project requirements. This adaptability allows for easy expansion or modification of the electrical system in the future.

However, it is important to consider the potential drawbacks of using conduit fittings. One of the main concerns is the additional labor and cost involved in the installation process. Compared to other wiring methods, such as surface-mounted conduits or cable trays, conduit fittings may require more planning and time for proper installation.

Furthermore, the rigid nature of conduit fittings can limit the flexibility of the electrical system. In situations where frequent modifications or reconfigurations are expected, other wiring methods that offer more flexibility may be more suitable.

Despite these considerations, conduit fittings remain a popular choice for many electrical installations due to their proven track record of providing reliable cable protection and ensuring compliance with safety regulations.

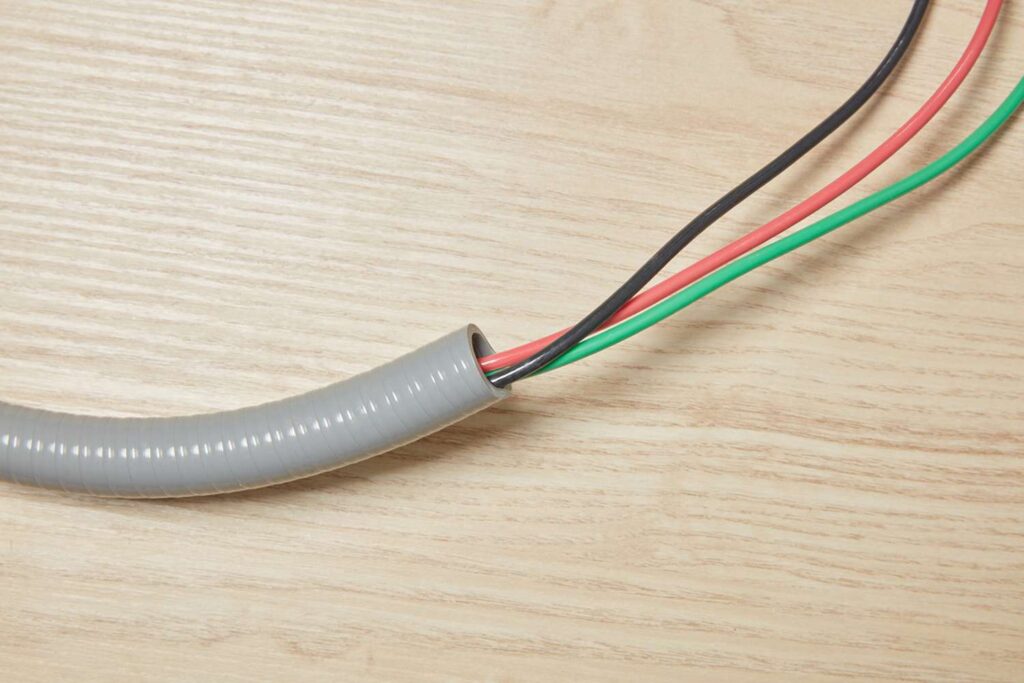

Exploring Cable Trays

Cable trays, on the other hand, are widely used for managing electrical cables in commercial and industrial settings. These trays provide mechanical support and protection to cables while allowing for easy access and maintenance. Understanding what cable trays are, their different varieties, and their advantages and disadvantages can help you determine whether they are suitable for your project.

What are Cable Trays?

Cable trays are structural systems used for supporting and organizing cables in a horizontal or vertical arrangement. They are typically made from materials such as steel, aluminum, or fiberglass, which offer strength and resistance to corrosion. Cable trays are designed to handle a wide range of cables, including power, data, and communication cables.

When it comes to cable management, cable trays are a popular choice due to their versatility and efficiency. These trays provide a safe and organized pathway for cables, reducing the risk of damage and ensuring proper functioning of electrical systems. They are commonly used in commercial buildings, data centers, manufacturing plants, and other industrial settings where cable management is crucial.

One of the key advantages of cable trays is their ability to accommodate different cable sizes and types. Whether you need to route power cables, data cables, or a combination of both, cable trays offer the flexibility to handle various cable arrangements. This adaptability makes cable trays suitable for projects with changing requirements or future expansions.

Different Varieties of Cable Trays

Cable trays come in various sizes, shapes, and designs to accommodate different cable arrangements and installation requirements. Some common types of cable trays include ladder trays, wire mesh trays, solid bottom trays, and trough trays. These varieties offer flexibility and versatility, making it easier to adapt to different project needs.

Ladder trays, as the name suggests, have a ladder-like design with horizontal rungs and vertical side rails. This design provides excellent ventilation and allows for easy access to cables for maintenance or modifications. Wire mesh trays, on the other hand, have a grid-like structure that offers good cable support while allowing for maximum airflow. Solid bottom trays, as the name implies, have a solid base that provides additional protection to cables and prevents dust or debris from falling through. Trough trays, with their U-shaped design, are ideal for applications that require additional cable support and protection.

Choosing the right type of cable tray depends on factors such as the type and quantity of cables, the environment, and the installation requirements. It is important to consider these factors to ensure optimal cable management and system performance.

Advantages and Disadvantages of Cable Trays

Cable trays offer several advantages that make them a popular choice in many electrical installations. They provide ample space for cable routing, allowing for easy installation, maintenance, and future expansions. With cable trays, cables can be easily organized and labeled, simplifying troubleshooting and reducing downtime in case of repairs or modifications.

In addition to their organizational benefits, cable trays also offer excellent ventilation and heat dissipation. The open design of cable trays allows air to circulate around the cables, preventing the buildup of heat and reducing the risk of overheating. This is particularly important for high-density cable installations or environments where heat-sensitive equipment is present.

However, it is worth noting that cable trays may require occasional cleaning to remove dust and debris that can accumulate over time. Regular maintenance is essential to ensure the optimal performance and longevity of the cables and the tray system itself. Additionally, the exposed design of cable trays may not be suitable for projects that require concealment or aesthetic considerations.

When considering the use of cable trays, it is important to weigh the advantages and disadvantages against the specific requirements of your project. Consulting with a professional electrical engineer or contractor can help you make an informed decision and ensure the successful implementation of cable tray systems.

Key Factors to Consider When Choosing Between Conduit Fittings and Cable Trays

When making a decision between conduit fittings and cable trays, there are several key factors to consider. These factors include cost implications, the installation process, maintenance and durability, safety concerns, and environmental considerations. Evaluating these aspects will help you make an informed decision that aligns with your project requirements.

Cost Implications

Cost is an important consideration for any project. Conduit fittings may require a higher initial investment due to the cost of materials and labor-intensive installation process. However, it is essential to consider the long-term cost implications as well. Cable trays, on the other hand, may be more cost-effective, especially for projects that require long cable runs or frequent changes. Additionally, cable trays offer the advantage of easy maintenance and modification, potentially reducing future costs.

Installation Process

The installation process is another crucial aspect to evaluate. Conduit fittings may require precise measurements, cutting, and threading of conduit pipes, which can be time-consuming and complex. This process may require skilled labor and specialized tools. On the other hand, cable trays offer a simpler installation process, allowing for easier adjustments and modifications as needed. This can save time and reduce labor costs, especially in projects with changing requirements or tight schedules.

Maintenance and Durability

Maintaining the electrical system’s reliability and longevity is essential. Conduit fittings offer excellent protection and durability, requiring minimal maintenance. The robustness of conduit fittings makes them suitable for harsh environments and areas with high mechanical stress. On the other hand, cable trays, although durable, may require occasional cleaning and inspection to ensure proper cable management and safety. However, cable trays offer the advantage of easy access to cables, simplifying maintenance and troubleshooting activities.

Safety Concerns

Safety should always be a top priority when choosing electrical components. Both conduit fittings and cable trays offer reliable cable management and protection. However, considerations such as fire resistance, electrical grounding, and protection against electrical interference may differ between the two options. Conduit fittings, being made of metal, provide inherent fire resistance and excellent electrical grounding. Cable trays, on the other hand, may require additional measures to ensure the same level of safety. Assessing the safety requirements of your project, such as the presence of flammable materials or the need for electromagnetic shielding, will help you make a well-informed decision.

Environmental Considerations

Environmental factors play a significant role in selecting electrical components. Conduit fittings, being made of metal, are highly recyclable and have a long lifespan, reducing waste and environmental impact. Cable trays, made of materials like steel or aluminum, also have good recyclability but may require periodic maintenance and replacement due to potential corrosion. Additionally, the choice between conduit fittings and cable trays may depend on the project’s environmental conditions, such as exposure to moisture, chemicals, or extreme temperatures. Evaluating the environmental impact and compatibility of the chosen option with the project’s surroundings is crucial for sustainable and long-lasting electrical installations.

Making the Right Choice for Your Project

After considering the factors discussed, making the right choice between conduit fittings and cable trays depends on your specific needs and project requirements.

Assessing Your Specific Needs

Start by assessing the scope, size, and complexity of your project. Consider factors such as the type of cables, ease of installation, required maintenance, and project budget. This evaluation will help you determine whether conduit fittings or cable trays are the better fit for your specific needs.

Consulting with Professionals

When in doubt, consult with electrical professionals or engineers who have experience in similar projects. They can provide valuable insights and recommendations based on their expertise, ensuring that you make the best decision.

Final Thoughts on Conduit Fittings and Cable Trays

Choosing the right cable management solution for your project is essential for safety, efficiency, and overall system performance. Conduit fittings and cable trays both offer unique advantages and considerations. By carefully evaluating the definition, function, types, pros and cons, as well as key factors in making the choice, you can ensure that your project benefits from an optimal electrical cable management solution.