There is no doubt that the efficiency of the concrete industry when it comes to construction cannot be undermined. However, Building Information Modeling (BIM) is another level of interest in the modern trend. BIM is the process of creating and managing all information about a construction project all through the project lifecycle. In project execution, a company can also collaborate with other companies to achieve a common goal.

On the other hand, the formwork can be demanding labor and time and costly to complete. When the pressure to meet a project intensifies, there is a need to rethink some procedures. These new methods can help contractors and formwork companies Sydney outperform their competitors and discover unique and effective ways to execute projects.

2D versus 3D Formwork Modelling

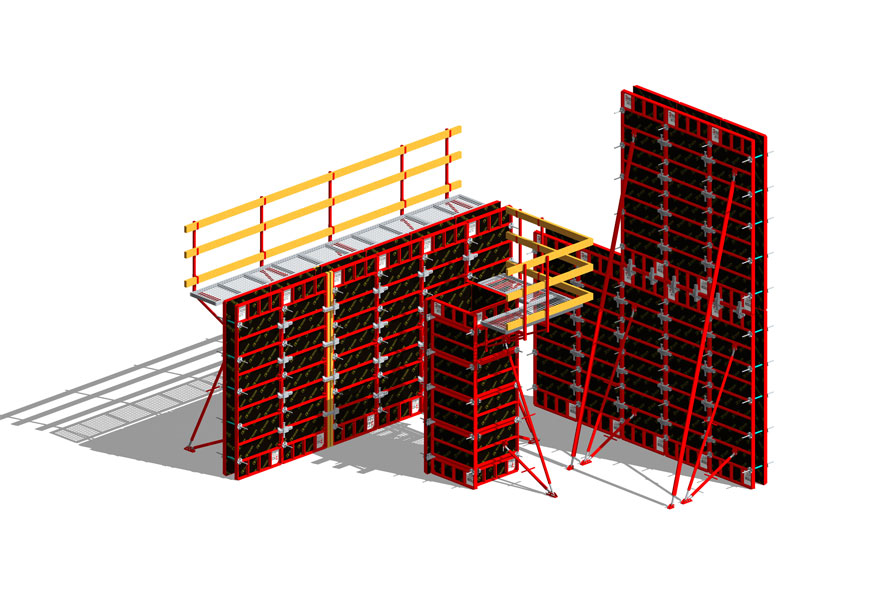

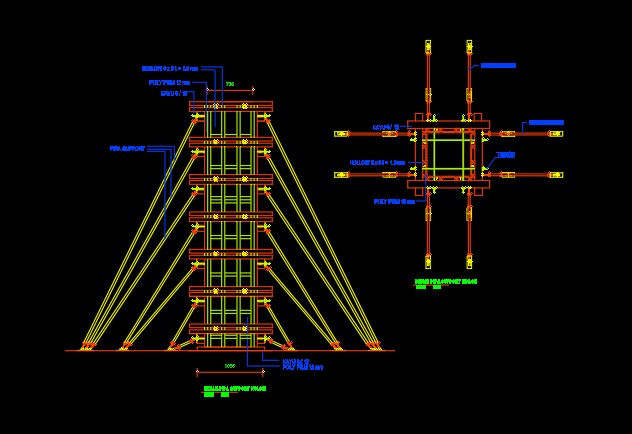

In the old days, the most prominent modeling method is the 2D Computer-Aided Drawings (CAD). And it seemed to be the only way to achieve formwork layout and design with the right plans. But today, construction companies have advanced from 2D methods to 3D modeling for concrete formworks. At the same time, the new approach to formwork integration to the construction plan requires that the planning tasks integrate the right path to the task at hand.

When we compare 2D to 3D designs, we will discover that the former is prone to error, guesswork, and other risks, which may eventually prove fatal. At the same time, it is limited in capturing the exact representation on all the sides of the feature that is represented on paper. Therefore, the 3D designs have a better grasp and presentation of the structure at hand more accurately. Also, while 2D shows a flat surface, the 3D drawing shows what the project looks like in real life.

Moreover, 2D drawings are of lesser quality and design, but the 3D drawings are easier to represent and less prone to errors. Otherwise, a potential inconspicuous error in a 2D will be well revealed in a 3D diagram, thereby averting a possibility for damage or costly rework.

Formwork Detailing and Planning with 3D

There is no doubt that the 3D representation has a highly accurate and accelerated formwork output. Similarly, the transition from 2D CAD to 3D drawing can also take formwork planning to the highest technical skill and ability level. However, it also comes with a more accurate, efficient, and highly productive output in construction projects. Below are the crucial features of the 3D drawing

- Automating takeoff

3D modeling is an integral part of the takeoff process of the construction project as a whole. And this happens almost automatically with 3D modeling. It is also a vital part of the planning and estimating process in the BIM, which interconnects the takeoffs and the model. Also, it is easier to visualize the formwork area material quantification through the 3D representation.

In addition, you can organize the information into the pouring type, location, sequence, and the planned formwork. It is advantageous for contractors and formwork companies in Sydney and shows a better way to line up the items according to the budget priority. This method also makes highly reliable and more accurate results possible.

- Construct accessibility

One of the peculiarities of having 3D designs is that it allows for the early discovery of potential project problems. Some of the apparent issues may include clashes in outlines and features and potential constructability problems at the early stage. When you see a 3D model drawing, the output already answers what exactly you want to build. In other words, you have an incredibly detailed representation that aligns with the project goals with formwork. Similarly, you can plan and construct your concrete pours in terms of the quality and quantity of the report. The 3D also gives room for easy additions and projected changes.

- Streamlining processes

Another way to enjoy 3D modeling is its work to model the tools on site effectively. When you need to place formwork components and accessories correctly, then a 3D geometry creates a better allowance for the placement. In other words, you better understand where to put your ties and clamps directly from the 3D model for formwork. At the same time, if you need to reference any part of the drawing and get the details, you can pull out any required reports.

Moreover, any change you make to the model can be easily updated to all the model documents. Also, the 3D model dramatically reduces the possibility of human error by reducing the otherwise disconnected workflows that you experience in 2D model pieces. The details of the constructible information allow more critical information to the project timeline and in a safer way for execution. Meanwhile, the process requires far lesser manual work.

- Ease of requirement communication to the field

3D models provide an easier way to communicate all the project requirements from the model to real-life in the area. A glance at the model already tells everyone what the work site will look like when the project is done. Therefore, it is easier to indicate and understand the formwork requirements. Tech-aided approaches such as tablets can enhance communication of ideas from the team leader to the workers very smoothly and efficiently. You can quickly draw up the needed information and communicate what you want at any point in time.

At the same time, you can easily update the information if there be any need to do so, and it regularizes all the documents and reports. In other words, there is no room for guessing what a piece of information on the model means. This model saves time describing the steps to achieving the formwork pattern or structure. But reduces the potential for error to the barest minimum, and formwork companies in Sydney have ample time to progress with the work.

Conclusion

In formwork structures by construction companies in Sydney, we can now conveniently look forward to what gives greater productivity and safety. Meanwhile, the modern methods of choosing 3D over 2D do not leave out the power to yield more economic value, save time, energy, and other valuable resources. At the end of the project, all parties can be satisfied with a job well done.